SLA Stereolithography from Advanced Prototyping

SLA for the Ultimate in Accuracy and Cost Effectiveness

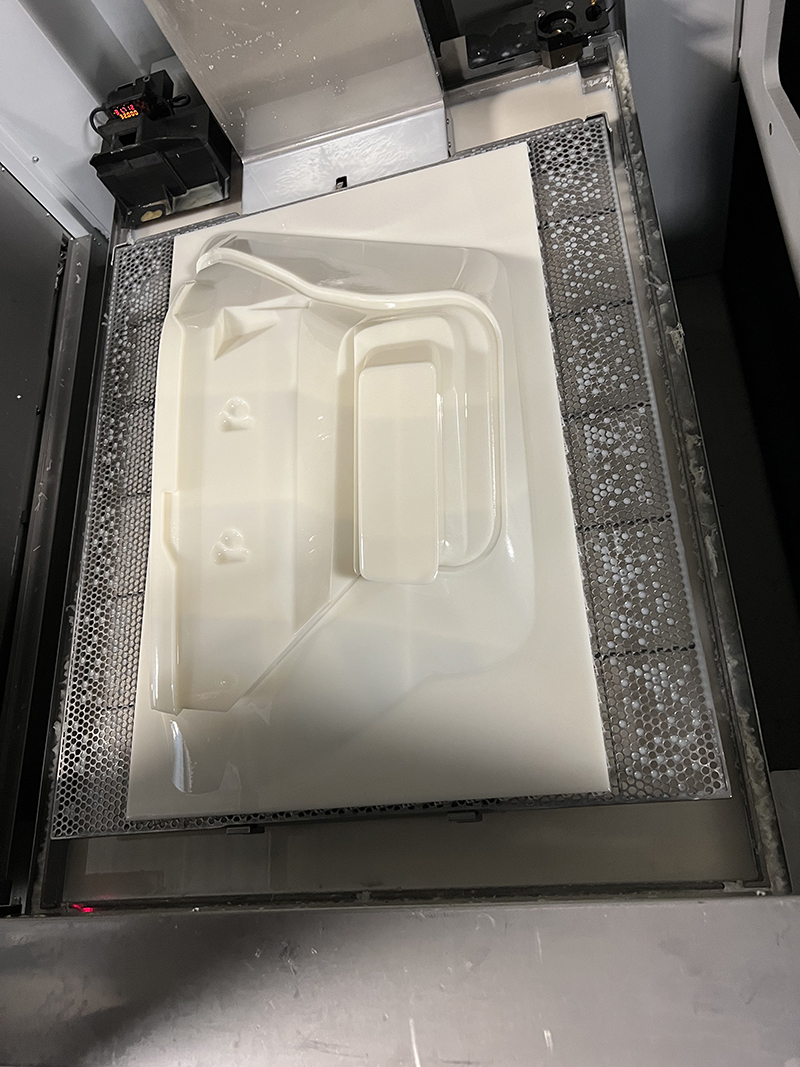

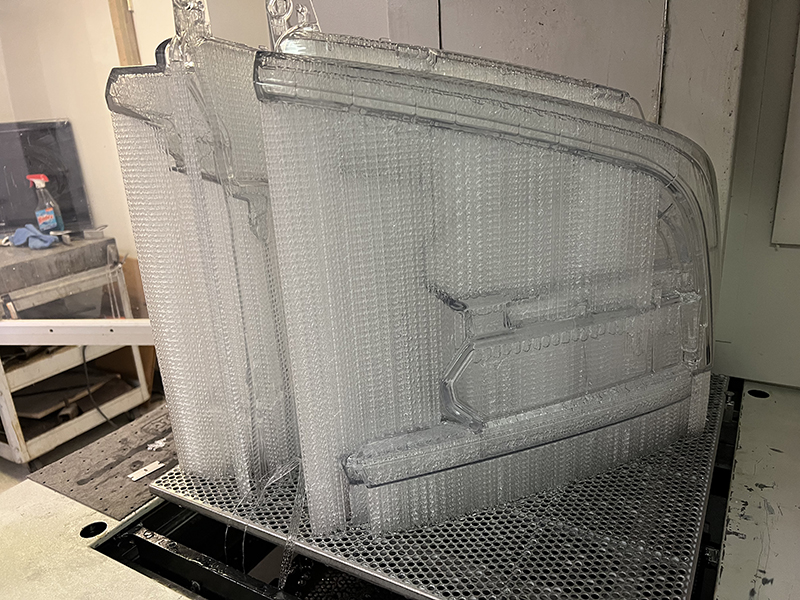

Stereolithography (SLA) is a "rapid prototyping" process which produces a physical, 3D model from a 3D CAD file. Our advanced SLA 3D printers produce exact plastic and composite material parts without the restrictions of CNC or plastic injection molding. With accuracy and surface quality of this level, you can produce low- to medium-run parts at a lower per-unit cost and build massive, highly detailed pieces faster. How fast? SLA prototypes can be made in a matter of hours.

Typically used for design verification, some SLA models are used to check form, fit and function, other models are used as a master to create a silicone mold to inject urethane into, to make duplicates.

SLA 3D Printing Features:

- Reduces per-unit costs on low- to medium-sized runs.

- Matches your exact mechanical and optical specifications with the broadest range of materials available.

- Cuts finishing time and enjoy the best surface quality available from any 3D printing.

- Identifies design flaws early with true-to-design accuracy and surface finish.

- Produces large, whole parts and cut both the time required for assembly and part weakness associated with attachment points.

- Streams the path from CAD or scan to final prototype part production.

There are several SLA materials to choose from. Click on the Product Data Sheets below for material specifications

Additive manufacturing - Upload your model via the Secure Online Quote System found at the top right of this page, in STL 3D CAD Model format.

SLA 3D Printing Applications:

- Aerospace

- Medical devices

- Manufacturing master patterns

- Automotive

- Electronics

- Orthodontics and dental

- Turbine production

You can download SLA Material Data Sheets linked below for more information:

SLA/Rigid - Accura-55 White

Simulate the look and feel of molded ABS with this tough and versatile plastic.

- Automotive interior parts

- Short-run production parts

- Electronic components

- Testing of functional assemblies

- Rigid and durable functional rapid prototypes

- Concept and marketing models

- Accurate, durable master patterns for urethane casting

Accura Xtreme Grey

Ultra-tough grey plastic with outstanding durability, accuracy and aesthetics to replace CNC-machined polypropylene and ABS articles.

Fast and easy to process, the Accura Xtreme material offers physical properties that are close enough to durable end-use plastics like ABS and polypropylene to make it ideal for functioning prototypes in demanding applications, as well as for short-run production projects.

Accura Xtreme is a grey plastic with the appearance of a final production part with outstanding durability, impact resistance, accuracy and a thermal resistance over 60° C.

SLA/Rigid - DSM-10122 Clear

DSM Somos® WaterClear Ultra 10122 is a next generation

optically clear resin with ABS like properties and good temperature resistance. In SLA rapid prototyping, it

produces colorless, functional, accurate parts that simulate acrylic in appearance. Based on the Oxetane

Advantage™, the parts also have improved water resistance over the original WaterClear 10120 resin.

WaterClear Ultra is a fast, low viscosity, general-purpose resin.

Advanced Prototyping are experts in these SLA prototyping services:

sla parts, rapid prototyping, stereolithography, 3d printing services, sla prototypes, ceramic 3d printing, 3d rapid prototyping, 3d printing of nylon, sla stereolithography, 3d printing parts, 3d prototyping service, rapid prototype development, carbon fiber prototyping, online quote for rapid prototyping, medical prototyping, automotive sla prototyping, 3d printing in plastic, aerospace part prototyping, three d printing services, 3d sla parts

1-888-764-8999

1-888-764-8999

Login

Login

Register

Register